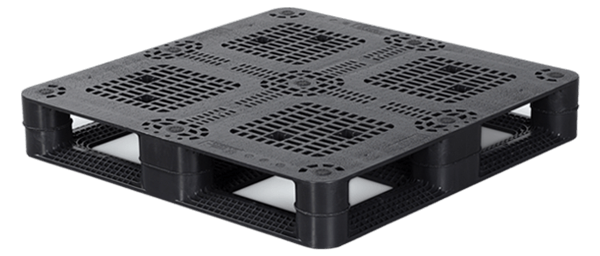

RU

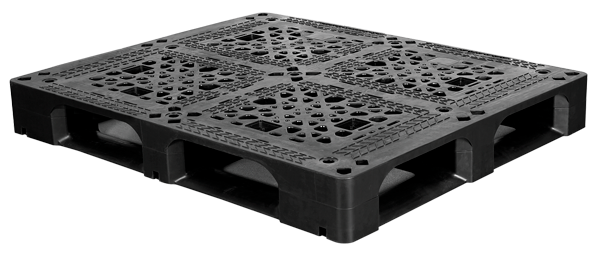

REUSABLE PALLET

There are several key components to consider when calculating an ROI for a plastic pallet project. Procurement cost over the lifetime of the pallet or trips is one of the biggest factors. A wooden pallet that only makes four or five trips before requiring repair or replacement is actually going to be much more expensive than and plastic pallet designed for 100 trips or more even at a significantly higher purchase price. Other components that should be included in a plastic pallet investment project are: product damage reduction, material handling maintenance reduction, downtime reduction, and transportation savings. Some intangibles that do not always make their way into an ROI, but are possibly even more impactful to be considered are: environmental sustainability, product branding, shelf-availability, employee safety and employee satisfaction.

- PERFORMANCE

- PLASTIC PALLETS ARE AN ASSET

You have Pallets Questions…

We have Pallet Experts.

Whether you’re looking for an entry-level reusable, one way or omni pallet, call us today!Weekday 8:00 am to 5:00 pm CT

Need To Know More ?

Read our Guide to Plastics Pallets.

Download Guide

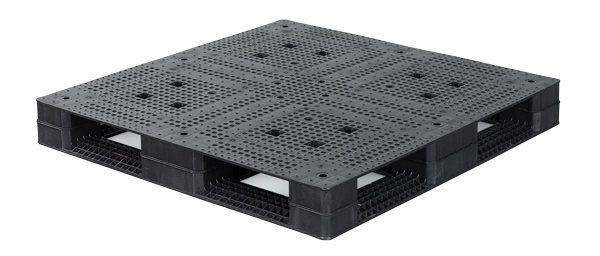

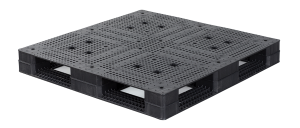

| MODEL | STACKABLE | SIZE | DYNAMIC CAPACITY | STATIC CAPACITY | RACK CAPACITY | WEIGHT | STEEL REINFORCEMENTSTEEL | MATERIAL | |

|---|---|---|---|---|---|---|---|---|---|---|

| TA01 | Yes | 40″ x 48″ | 2,800 lbs | 17,600 lbs | 1,100 lbs (only with central rack support). | 37 lbs | No | High-density polyethylene provides excellent unit load performance. | VIEW MORE |

| TA03 | Yes | 48″ x 48″ | 2,800 lbs | 22,000 lbs | 1,600 lbs | 58 lbs | No | High-density polyethylene provides excellent unit load performance. | VIEW MORE |

| TA20 | Yes | 40″ x 48″ | 3,700 lbs | 33,000 lbs | 3,300 lbs | 58 lbs | Standard with multiple configurations. | High-density polyethylene provides excellent unit load performance. | VIEW MORE |

| TA50 | Yes | 37″ x 37″ | 4,400 lbs | 26,000 lbs | 2,400 lbs | 39 lbs | No | High-density polyethylene provides excellent unit load performance. | VIEW MORE |

| TA100 | Yes | 40″ x 48″ | 3,700 lbs | 33,000 lbs | 3,300 lbs | 51 lbs | Standard with multiple configurations. | High-density polyethylene provides excellent unit load performance. | VIEW MORE |

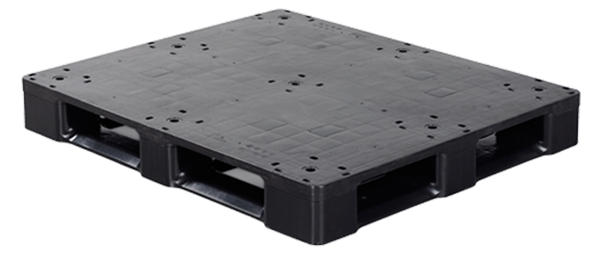

| MODEL | RACKABLE | SIZE | DYNAMIC CAPACITY | STATIC CAPACITY | RACK CAPACITY | WEIGHT | STEEL REINFORCEMENTSTEEL | MATERIAL | |

|---|---|---|---|---|---|---|---|---|---|---|

| TA03 | Yes | 48″ x 48″ | 2,800 lbs | 22,000 lbs | 1,600 lbs | 58 lbs | No | High-density polyethylene provides excellent unit load performance. | VIEW MORE |

| TA20 | Yes | 40″ x 48″ | 3,700 lbs | 33,000 lbs | 3,300 lbs | 58 lbs | Standard with multiple configurations. | High-density polyethylene provides excellent unit load performance. | VIEW MORE |

| TA50 | Yes | 37″ x 37″ | 4,400 lbs | 26,000 lbs | 2,400 lbs | 39 lbs | No | High-density polyethylene provides excellent unit load performance. | VIEW MORE |

| TA100 | Yes | 40″ x 48″ | 3,700 lbs | 33,000 lbs | 3,300 lbs | 51 lbs | Standard with multiple configurations. | High-density polyethylene provides excellent unit load performance. | VIEW MORE |